Laboratories

The department has established well equipped laboratories which adequately fulfill the requirements of undergraduate course. These labs are equipped with all the modern mechanical testing, measuring and other instruments.

Manufacturing Science Lab:

Shaping Machine, Power Hacksaw Machine, Cylindrical Grinding Machine, Surface Grinding Machine, Bench Grinder, Sheet Bending Press Brake, Fly Press, Injection Moulding Machine, Pipe Bending Machine, Sheet Rolling Machine, Sand Sieve Shaker, etc

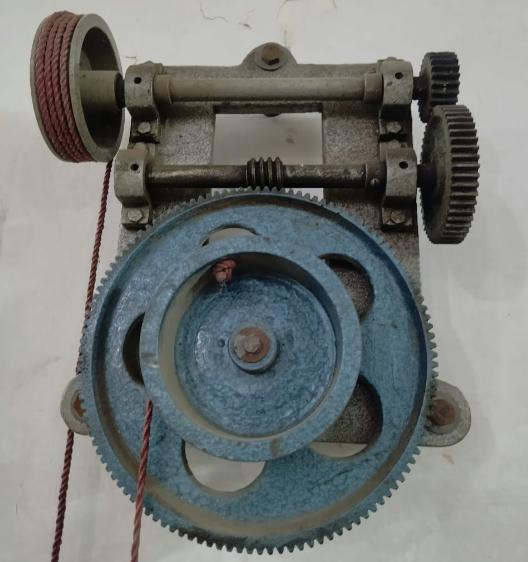

Theory of Machines Lab:

Static & Dynamic Balancing Apparatus, Universal Governor Apparatus, Motorized Gyroscope, Epicyclic Gear Train, Whirling Of Shaft Demonstrator, Single Slide & Double Slide crank Mechanism, Clutch Models, Brake Models, etc

Engineering Mechanics Lab:

Universal Testing machine, Torsion testing machine, Rockwell Hardness Tester, Impact Testing Machine, Fatigue Testing Machine, Screw Jack Apparatus, Worm & Worm Wheel Apparatus, Simply supported & Cantilever beam, etc

Thermodynamics Lab:

Single Cylinder Four Stroke Diesel Engine Test Rig, Steam Engine, Steam Turbine, Boilers, Engine Cut Section, Fiat Engine Model, Two stroke and Four stroke Petrol and Diesel Engine Models, Gas turbine model, etc

Metrology Lab:

Micrometer, Depth Micrometer, Dial Gauge, Height Gauge, Sine bar, Wire Gauge, Temperature, Displacement, Force, Vibration Measuring Setup, etc

Material Science & Testing Lab

Universal Testing machine, Torsion testing machine, Inverted metallurgical Microscopes, Abrasive disc cut off machine, Metallurgical double disc Polishing Machine, Muffle Furnace, Specimen Leveler, belt sander, etc.

Refrigeration and Air Conditioning Lab:

Refrigeration Test Rig , Air-conditioning Test Rig, Ice Plant Test Rig, Window AC Test Rig, Display Board (Cut Sectional Model),etc.

Fluid Mechanics Lab:

Flow Measurement Orifice & Venturi Meter, Wind Tunnel, Bernoulli’s Theorem Apparatus, Apparatus For Orifice & Mouth Piece, Reynold's Apparatus, Impact Of Jet Apparatus.

Fluid Machinery Lab:

Francis Turbine Test Rig, Pelton Turbine Test Rig, Centrifugal Pump Test Rig, Reciprocating Pump Test Rig, Hydraulic Ram Test Rig, Double Stage Air Compressor Test Rig, etc

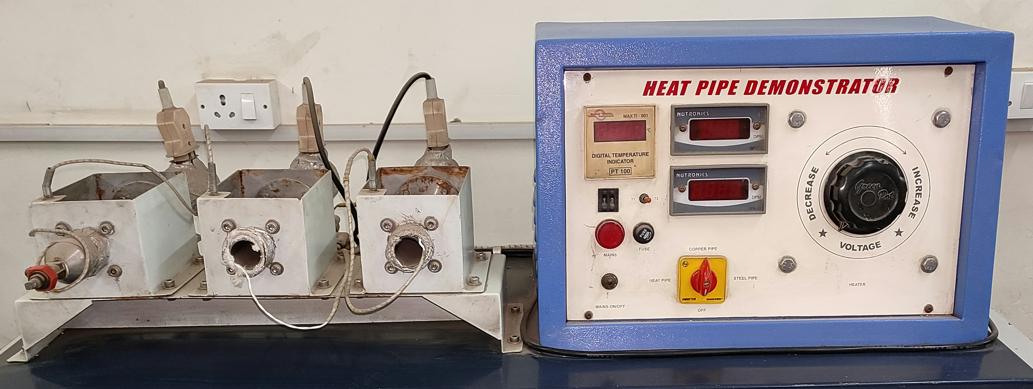

Heat and Mass Transfer lab:

Heat Pipe Demonstrator , Parallel and Counter flow Heat Exchanger, Stefan Boltzman Apparatus, Thermal Conductivity Of Liquid Apparatus , Heat Transfer in Natural Convection, Heat Transfer Through Composite Walls , Heat Transfer Through Lagged Pipe etc

Workshop:

Carpentry Shop: Wooden Lathe, Circular Saw Machine, etc Fitting Shop: Vices, Fittings Tools Like Hacksaw, Files, Punches, taps , dies, Machine Shop: All Geared Lathe machines, Vertical Drilling Machine, etc Smithy Shop: Furnace, Anvil, Tongs, Hammer, etc. Foundry Shop: Moulding Boxes, Rammer, Riser, Furnace, etc Welding Shop: Arc Welding Machine, Gas Welding Equipment, TIG Welding Machine, Spot Welding Machine, etc

CAD CAM Lab:

CNC Lathe machine

CNC Milling machine

Softwares like AutoCAD, MATLAB, Pro-Engineer(Creo), Ansys, etc

Automobile Engg Lab:

Gear box (cut section model), 4-Stroke 4- cylinder Petrol engine test rig

1 cylinder 4 stroke Diesel engine test rig

Steering mechanism

Automobile braking system

Ignition system of I C Engine

Fuel supply system of I C Engine

Fuel supply system of CI Engine, etc

Softwares

Department provides exposure to its students to softwares like

AUTO CAD Mechanical

AutoCAD Mechanical software is a mechanical engineering design and documentation solution that supports Building Information Modeling workflows. It is used for designing, drafting and documentation, analysis, defining workflows of mechanical projects.

ANSYS

ANSYS offers a suite of engineering simulation software for engineers and designers to virtually analyze how their products (and thousands of parts in them) work in real world environment, at an early stage of product design.

ANSYS software is being used across a wide range of industries to analyze various performance parameters such as signal integrity, electromagnetic interference, thermal issues, and mechanical failure.

PROE or CREO

Creo, from PTC, is a complete suite of concept design, 2D, 3D, simulation & analysis engineering software. What is unique about Creo is that it has taken into account how product design and development is done in modern days, using diverse tools, with the participation of people of a variety of skills, from different geographical locations.

The key promises of Creo tools include: faster time-to-market, product quality, design efficiency; minimum errors, less scrap and rework.

Edgecam 2015 R1

Edgecam is a market leading computer aided manufacturing (CAM) system for NC part programming. With unparalleled ease of use and sophisticated tool path generation, it’s the only CAM system you’ll need for milling, turning and mill-turn machining.

Edgecam utilizes your in house knowledge and experience to drive the CAM process with automation tools to suit different applications - allowing you to maintain your competitive edge.

Notice Board

- Guidelines for Seminar

- Practical Summer Training Schedule

- Seminar Topics Even 2018 19

- Guidelines for Industrial Training

- Previous year seminar topics

- Industrial visits organized

- Innovent Group

- Project Report Sample

- Project Templates Previous Years

- Project Guidelines Project Diary Project Report Format

- Software Training Conducted

- Sports Activities

- Cultural Activities

- Seminar Sample Report

- Seminar Sample PPT

- Industrial Training Sample Report

- Industrial Training Sample PPT